Dust free, loss free, powder feeding, wetting and dispersing to a completely des-agglomeration in one machine. No external vacuum generation or additional external air is necessary. By combining all processing steps into one machine, enormous rationalization potential is offered. Production time is minimized, partial processing steps are completely avoided, production cost is reduced to a minimum, energy saving. The basic idea of the IWD technology is that not only the powder is wetted, but also dispersed into a liquid under vacuum. Agglomerates are avoided, better reactivity, higher efficiency of the raw material and higher product quality are the results.

Operating Principle

The IWD works together with a process tank in recirculation. After the machine is started, the liquid flows to the IWD and pumped back to the process tank. Due to the strong pumping action of the rotor, a strong negative pressure is created in the process chamber of the IWD. This vacuum which draws the powdered solids into liquid.

Benefits of IWD

• Partial processing steps are completely eliminated and process energy saving more than 50%;

• Clean process due to dust-free and loss-free powder induction, production cost is reduced;

• Production times are minimized due to dispersion quality improved;

• Powders are not only wetted but dispersed into a liquid under vacuum. Reduction or elimination of wetting agents;

• Deaeration of the product following powder intake. Reduction or elimination of defoamers;

• Flexible, variable batch sizes and easy for color changing;

• No adhesion to the vessel or installed components.

Technical Data

| 型号 Model | IWD20 | IWD40 | IWD60 | IWD80 | IWD100 | |

| 设备功率 Motor power | kw | 7.5~15 | 30~45 | 37~55 | 55~90 | 90~132 |

| 工作转速 Max. speed | r/min | 0~5000 | 0~3600 | 0~3600 | 0~3600 | 0~3600 |

| 工作流量 Flow during circulation | m³/h | 10~150 | ||||

| 粉体输送 Powder intake | kg/h | 1~20,000 (依粉料种类而定 depending on the type of powder used) | ||||

| 最大粘度 Max. viscosity | mPas | 200,000 (依机器管道大小而定 depending on size and use of the machine) | ||||

| 可选配 Options | explosion proof execution, certifications | |||||

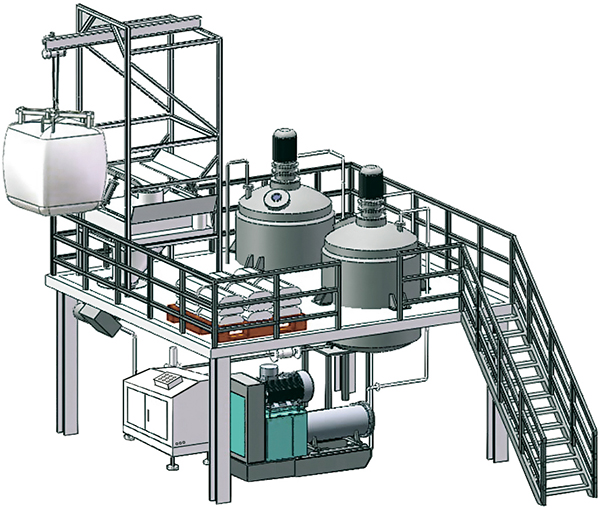

Dust Free Process Module, it can include:

Advantage

• Automatic production available

• Product management from start to finish with quality control and guarantee

• Clean process for environmental protection

• Product area is minimized

• Installation and operation on one level