无尘、无损耗地将团聚在一起的粉料在一台机器内达到完全的润湿分散和解聚,不需要额外的泵或辅助的气体。由于在一台机器上实现了所有分散的工艺,产生了很多合理的潜力。如生产时间最小化,减少部分的工艺步骤,生产成本降至最低,以及更节能与环保。IWD在线润湿分散机的基本概念不仅是粉末被润湿,最重要的是在真空下分散。在真空下避免了团聚,从而获得更好的分散效果、更高的原料效率和更高的产品质量。

Dust free, loss free, powder feeding, wetting and dispersing to a completely des-agglomeration in one machine. No external vacuum generation or additional external air is necessary. By combining all processing steps into one machine, enormous rationalization potential is offered. Production time is minimized, partial processing steps are completely avoided, production cost is reduced to a minimum, energy saving. The basic idea of the IWD technology is that not only the powder is wetted, but also dispersed into a liquid under vacuum. Agglomerates are avoided, better reactivity, higher efficiency of the raw material and higher product quality are the results.

工作原理 / Operating Principle

IWD在线润湿分散机配合一循环分散罐达到固液混合的目的。IWD机器启动后液体由循环罐流到主机腔体再打回循环罐。由转子形成的超大流量从而产生极大的负压,这接近真空的负压将粉料吸到液体中最终成为浆料再回到循环罐。

The IWD works together with a process tank in recirculation. After the machine is started, the liquid flows to the IWD and pumped back to the process tank. Due to the strong pumping action of the rotor, a strong negative pressure is created in the process chamber of the IWD. This vacuum which draws the powdered solids into liquid.

设备优点 / Benefits of IWD

• 粉体在接触到液体时瞬间被润湿完全省去这步骤,可节能超过50%以上;

• 无尘,无粉料损耗的完全洁净的生产工艺降低了生产成本;

• 分散效果提升的同时也缩短了产品生产的时间,尤其是砂磨机的研磨时间;

• 粉料在真空环境下不仅被润湿,同时也完成最佳的分散,分散剂用量有减少的可能性;

• 粉料吸入时先脱气,不会导入更多的空气,从而减少消泡剂的用量;

• 弹性化的批量大小不受限制,更容易清洗换色;

• 机器和分散罐不会有粉料沾粘或或结皮现象。

• Partial processing steps are completely eliminated and process energy saving more than 50%;

• Clean process due to dust-free and loss-free powder induction, production cost is reduced;

• Production times are minimized due to dispersion quality improved;

• Powders are not only wetted but dispersed into a liquid under vacuum. Reduction or elimination of wetting agents;

• Deaeration of the product following powder intake. Reduction or elimination of defoamers;

• Flexible, variable batch sizes and easy for color changing;

• No adhesion to the vessel or installed components.

技术参数 / Technical Data

| 型号 Model | IWD20 | IWD40 | IWD60 | IWD80 | IWD100 | |

| 设备功率 Motor power | kw | 7.5~15 | 30~45 | 37~55 | 55~90 | 90~132 |

| 工作转速 Max. speed | r/min | 0~5000 | 0~3600 | 0~3600 | 0~3600 | 0~3600 |

| 工作流量 Flow during circulation | m³/h | 10~150 | ||||

| 粉体输送 Powder intake | kg/h | 1~20,000 (依粉料种类而定 depending on the type of powder used) | ||||

| 最大粘度 Max. viscosity | mPas | 200,000 (依机器管道大小而定 depending on size and use of the machine) | ||||

| 可选配 Options | explosion proof execution, certifications | |||||

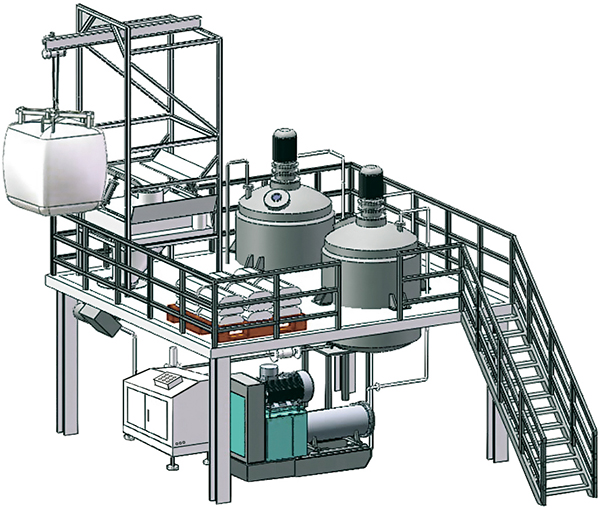

无尘生产模块 Dust Free Process Module, it can include:

模块优点 / Advantage

• 全自动生产

• 全自动生产

• 产品生产自始至终都有质量管控和保证

• 环保清洁工艺

• 生产所需面积最小化

• 所有设备均在同一楼层

• Automatic production available

• Product management from start to finish with quality control and guarantee

• Clean process for environmental protection

• Product area is minimized

• Installation and operation on one level