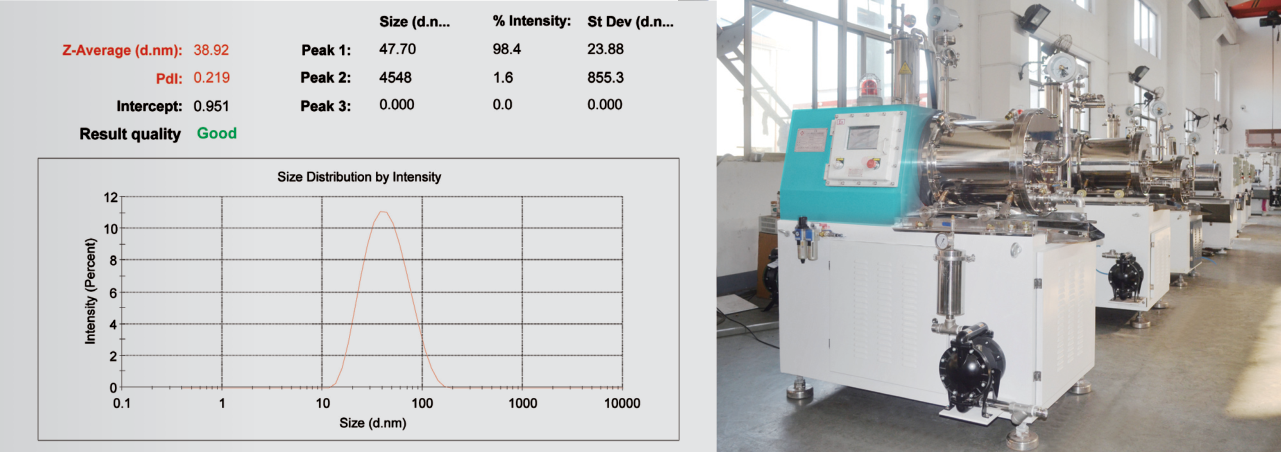

CDP系列纳米砂磨机采纳欧洲先进设计标准,流量大,控温能力好,能量转化率高,达成纳米级研磨时粒度分布范围窄。

CDP系列纳米砂磨机广泛应用在陶瓷、墨水、喷墨、色彩过滤器的分离剂、功能性陶瓷、锂电池材料、热敏纸、电子抛光液、纳米色浆、农药等纳米研磨领域。

CDP series adopted advanced European design standards with ample flow, good temperature controlling ability and energy transformation ratio to achieve the narrow degree of grain size distribution range of nanometer grade.

CDP series have widely used in ceramics, ink, color filter separating agent, functional ceramic, lithium battery materials, thermal paper, electronic slurry, nano paste, pesticides and other fields of nano grinding.

工艺特性 Operational Characteristic

采用循环研磨工艺,环保节能、劳动强度小。配制好的原始浆料,经过第一遍粗略研磨后,泵入循环搅拌罐,经底部泵输送进入纳米研磨机;一边经过研磨后送入循环罐,与未曾研磨过的物料通过搅拌机快速混乱,一边又通过底部泵入砂磨机,周而复始直到达成研磨要求。一般而言,罐的容积是砂磨机流量的1/4。

With the circular grinding process, environmental protection,energy saving, and small labor intensity, after the original slurry preparation and the first rough grinding, pump into the circle mixing tank and delivery into the nano grinding machine through the bottom pump. Make rapid mixer chaos with no grinding materials into the circulation tank at the same time deliver into it after grinding and into the sand mill through the bottom pump. Come full circle until it reached the requirement of grinding. Generally speaking, the volume of the tank is 1/4 of the sand mill flow.

优势表现 Advantage Performance

◆ 全新设计的静态离心分离装置,流量大,出料顺畅;

◆ 可以使用0.1mm以上的研磨介质;

◆ 以黄金分割比为标准的转子与筒体布置方式,可以有效降低磨损,增大能量利用率,达成最佳的使用效果;

◆ 更加优化的整机设计,设备整体稳定性更可靠;

◆ 高精密加工的零部件,精湛的装配工艺,保证了设备运行的稳定性;

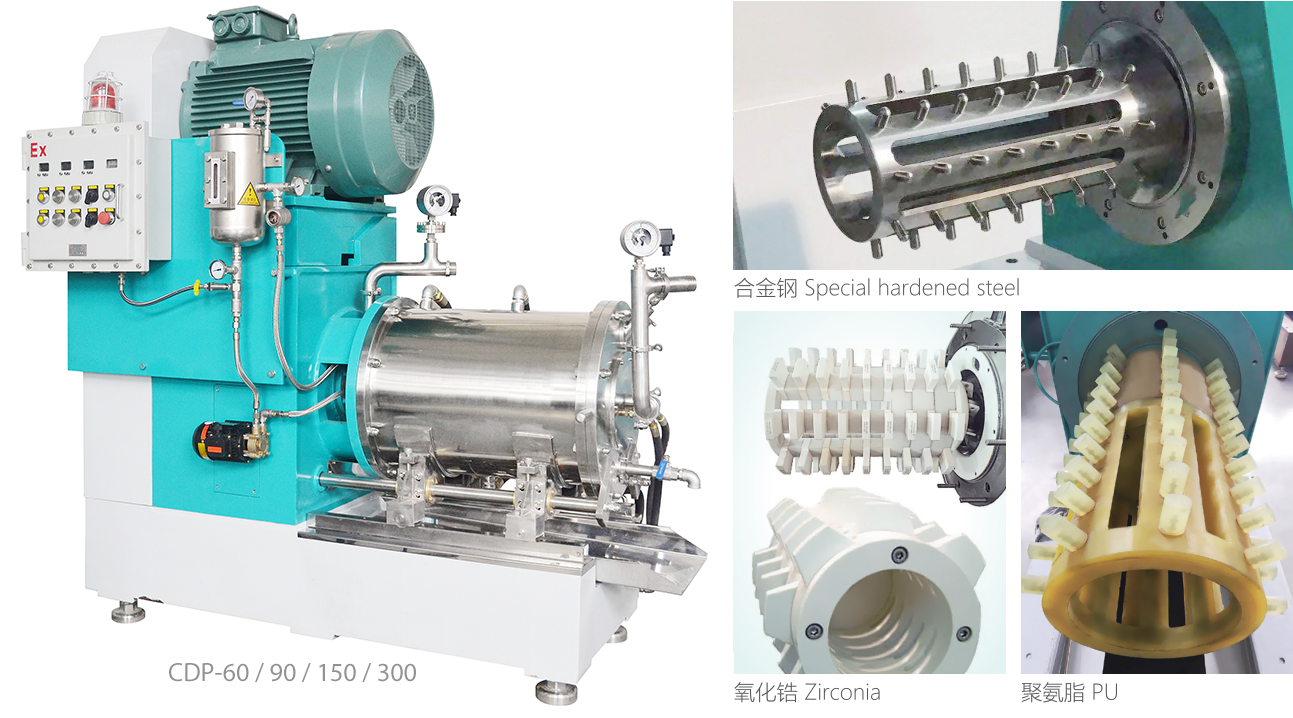

◆ 材质:根据不同产品,可以选择碳化硅、氮化硅、氧化锆、聚氨酯、硬质合金等材料;

◆ 多重冷却模式,可以有效的降低研磨产生的热量。

◆ The new design of the static centrifugal separation device with large flow and material flow smoothly;

◆ Could use the grinding media above 0.1mm;

◆ Using the rotor and cylinder arrangement with standards of golden section ratio,it can effectively reduce wear and tear, increase energy efficiency, and achieve the best use effect;

◆ More optimized design of the whole machine to make more reliable of the overall stability of the equipment;

◆ Ensure the stability of equipment operation with parts of high precision machining and exquisite assembly process;

◆ Material quality:according to different products, you can choose silicon carbide, silicon nitride, zirconium oxide, polyurethane, hard alloy and other materials;

◆ Multiple cooling mode, can effectively reduce the heat produced by grinding.

技术参数 Technical parameters

| 型号 Type | CDP-6 | CDP-10 | CDP-15 | CDP-20 | CDP-30 | CDP-60 | CDP-90 | CDP-150 | CDP-300 |

研磨腔容积 | 6 | 10 | 15 | 20 | 30 | 60 | 90 | 150 | 300 |

主机功率 | 7.5~15 | 18.5~22 | 18.5~22 | 22~30 | 45 | 75~90 | 110~132 | 160~185 | 250~315 |

研磨介质 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 | 0.2~2 |

整机重量 | 600 | 750 | 1200 | 1300 | 1500 | 3000 | 4000 | 6000 | 7500 |