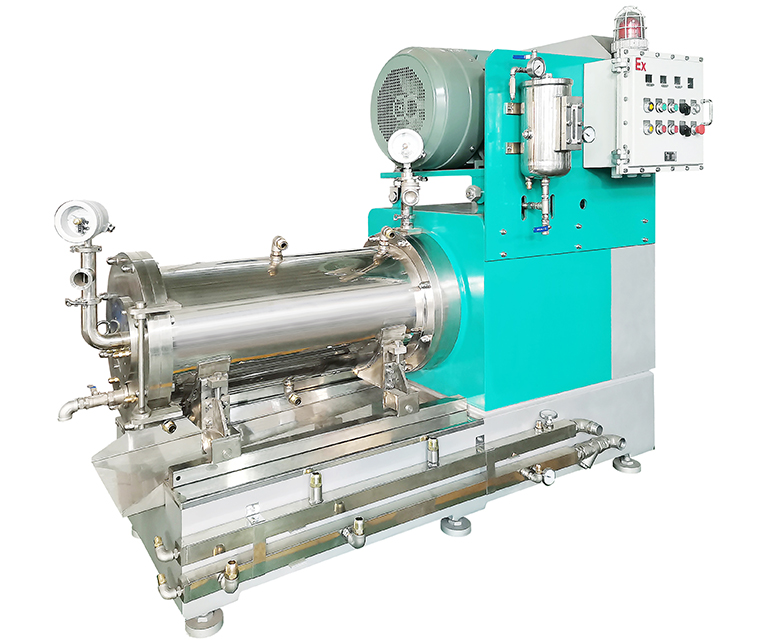

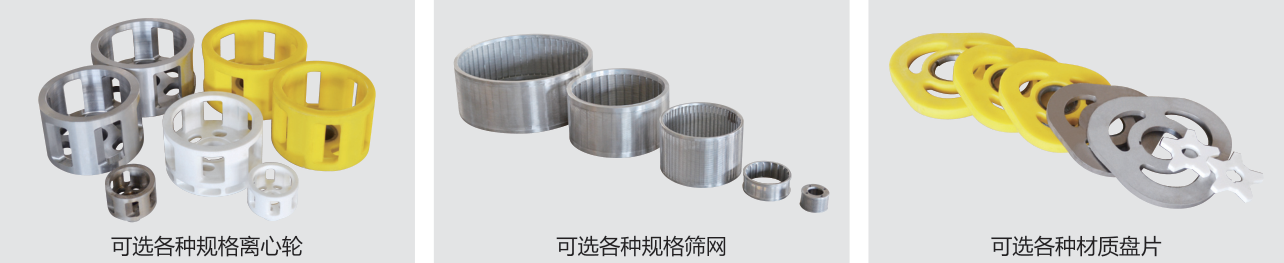

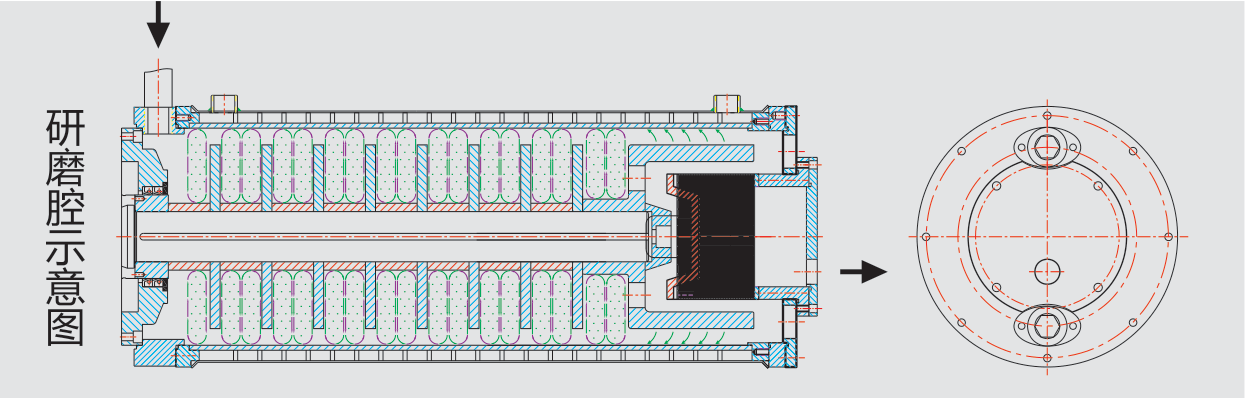

通惠全新机型CDS大流量砂磨机采用新研发功能部件为你提供更经济的湿法研磨工艺和技术,高效率研磨盘片和超大离心轮及筛网使研磨珠子能更好的分布在研磨腔,利用离心动态分离式筛网提高流量,研磨珠能安全的分离,甚至在高流量时高效率的分离系统发挥作用,包含的单元有:●离心轮及筛网和整合的盘片;●特殊之超大筛网。

The new full-volume Dynamic-Centrifugal-Cartridge-System offers optimized energy saving wet milling technology by con-sequent combination of a multitude of newly developed and ideally matching functional elements. High efficiency grinding discs with a large-surface slotted sieve to get the better beads distributed in the mill chamber. Enhanced flow rate capability by centrifugal implement screen. Operationally safe separation of grinding beads even with particularly high flow rates due to the highly efficient separator system, consisting of: ●Deflector cage with integrate grinding disc. ●Large-surface slotted sieve.

机器的概念和特点 Concept and main features

● 排除腔体内无效径向力

● 可更换各种材质的内腔体

● 可更换前后端盖和易磨损备件为耐磨损材质

● 特殊盘片和轴心设计

● 离心动态分离式筛网

● Elimination of all radial openings in the mill chamber

● Allowing for installation of exchangeable, through-hardened inner liner

● Exchangeable, through-hardened front & end plates and hardened wear bushings at exposed locations

● Combination of neutral and conveying high intensity agitator discs, specific design featuring increased diameter

● Bead retention by centrifugal implement screen

CDS大流量砂磨机优点 CDS Large flow rate grinding mill

● 介于高能量密度和传统砂磨机之间的高效率研磨设备

● 通常使用单道次研磨工艺

● 特殊的研磨珠保持设计

● 特殊之超大筛网清洗设计

● 适用于高磨损产品

● 研磨分散大批量涂料

● 利用离心动态分离式筛网提高流量

● 容易更换产品接触部之备件

● Closing gap between high enery density mills and convention mills

● Usually singal pass process

● Unique media retention device

● Unique cleaning feature of large surface screen

● Advantageous grinding of abrasive products such as marine pains, antifouling ,heavy duty protective coatings

● Dispersing grinding of bulk paint (primer, filler)

● Enhanced flow rate capability by centrifugal implement screen

● Easy to exchange product contact parts

技术参数 Technical parameters

| 型号 Type | CDS-20 | CDS-30 | CDS-50/60 | CDS-100 | CDS-300 | CDS-500 | CDS-1000 |

主机功率 | 18.5~22 | 22~30 | 37~45 | 55~75 | 90~132 | 160~200 | 315~355 |

研磨腔容积 | 20 | 30 | 50/60 | 100 | 300 | 500 | 1000 |

产品最高流量 | 50~250 | 100~500 | 200~1000 | 250~2500 | >2000 | >3000 | >5000 |

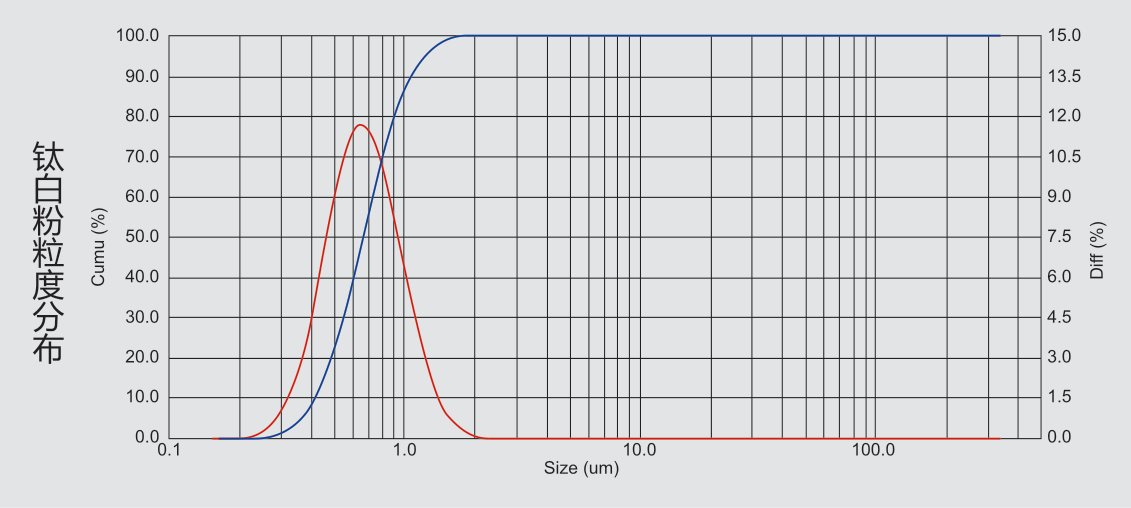

研磨珠粒径可选用0.2mm~1.0mm,研磨物料至亚微米甚至纳米级别变得轻松自如。保守估算同等条件下研磨效率至少是传统砂磨机的2倍以上。

We can choose the grinding beads of diameter 0.2mm~1.0mm to grind materials, and it easily make materials' finess achieved submicron even nanometer. On a conservative estimate and a equal conditions, the grinding efficiency is at least 2 times more than the traditional sand mill's